SustainabilitySocietyOccupational safety and health

At TOCALO, we are committed to the upkeep and improvement of a facilitative work environment

where employee health and safety is an important consideration.

In addition, we are committed to achieving zero occupational accidents and are working to create safe work environments where employees can work with greater comfort and peace of mind.

Occupational safety and health

2025 safety and health policy

TOCALO’s safety and health policy is based on the principle that “safety takes precedence over everything.” Under this policy, we comprehensively identify and mitigate risks by implementing risk assessment activities, while maintaining and improving work environments and eliminating accidents and injuries by prioritizing safety and health and working to safeguard and enhance the health of all employees. We will strive to create a bright and rewarding workplace through the following measures.

- Complying with laws and regulations related to safety and health related to our business and relevant internal regulations

- Communicating with all employees, systematically carrying out occupational health and safety activities (inspections, patrols, health and safety education, and work environment surveys) with the participation of all employees, with the aim of raising safety and health awareness

- Aiming to reduce risk factors for accidents and serious incidents by carrying out risk assessments and analyzing occupational accidents and near misses, by increasing visualization through the 5S cycle, by applying the JIS Q 45100 standard, and by implementing workplace improvement activities

- Prioritizing health management and mental health so that employees can enjoy good physical and mental health

- Thoroughly providing health & safety education for new employees beginning when they join the company

- Promoting the safety activities of on-site partner companies and subcontractors

Occupational Health and Safety Management System

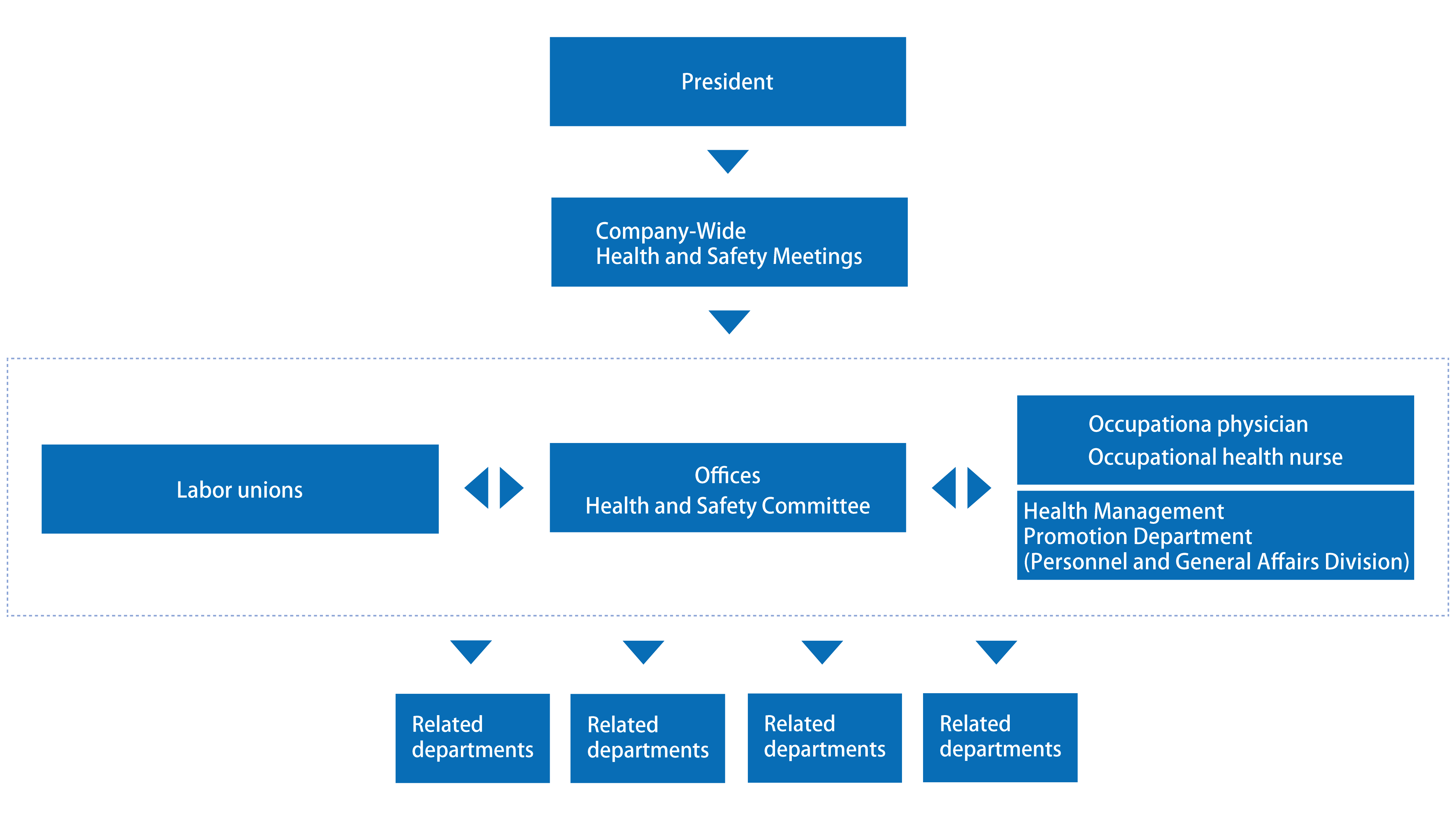

TOCALO maintains an occupational health and safety management system headed by the president and dedicated to providing a comfortable and safe work environment. Safety and health committees at each business site meet each month to assess workplace risks and provide feedback to employees on the assessment results. Risk information issued by the committee is shared at Company-wide health and safety meetings headed by the General Manager of the Production Headquarters. The Company also works with each business site, the Health Management Promotion Department, labor unions, occupation health nurses, and external experts (occupational physicians) to raise employee safety awareness and continuously improve health and safety conditions.

Industrial safety and health initiatives

We strive to maintain and improve a comfortable work environment that gives consideration to safety and health, as well as enhance various systems related to welfare in compliance with the Labor Standards Act and the Industrial Safety and Health Act. Parallel to this, each business site has established its own measures to ensure safety and minimize damage in the event of an occupational accident.The Company makes concerted efforts to prevent occupational accidents and vigorously promotes safety and health measures.

Specifically, we hold monthly meetings of occupational safety and health committees, where advice is obtained from external experts (industrial physicians) regarding health issues and safety and health matters. We also carry out regular safety patrols to address any risk factors that could cause accidents or serious incidents.

Effort is also made to raise safety awareness by providing education centered on safety education to new employees entering the Company that is and focusing on foreman training that is based on guidance from external consultants.

VOICE

Cultivating a workplace safety culture that prevents accidents and injuries

Kenichi Ishii

Kobe Plant

As the safety officer and health manager at the Kobe Plant, I am responsible for day-to-day health and safety measures. While practices such as pre-work hazard prediction and near-miss reporting are important, they tend to become routine and lose freshness over time. I am therefore prioritizing the planning and implementation of projects that will generate interest. For example, during National Safety Week, which is held each year from July 1 to 7, we carried out workplace hazard prediction activities at different workplaces than usual. This brought freshness to the activities and resulted in new insights.

When working to prevent occupational accidents, I focus in particular on developing our workplace safety culture. In the past, we tended to be a little lax in certain respects, such as wearing protective gear and following work procedures. However, we have now firmly established a culture of reciprocal checking for compliance, regardless of rank. This might seem trivial, but I see it as progress toward the development of our safety culture.

We cannot make progress on health and safety initiatives without the participation of all employees. I want us to move forward toward the elimination of accidents and serious incidents by encouraging all TOCALO employees to participate actively by sharing ideas and engaging in dialogue.

Initiatives to create a comfortable work environment

In recent years, summer heat has become increasingly severe, and temperatures at manufacturing sites have been higher than before, increasing stress on employees. The higher the temperature gets, the greater the risk of heat stroke becomes, so this could adversely affect the health of our employees. To prevent such risks, we are firstly improving our air-conditioners. Air-conditioners are installed at most of our flat panel display (FPD) and semiconductor processing plants (FPD and semiconductors make up just over 50% of total sales), and we are actively introducing them at other worksites as well. Measures other than air-conditioning are implemented at sites as required, such as exhausting hot air and steam generated in operations to the outside, reducing outdoor heat input through the use of heat-shielding coating, and installing large-scale air blowers. In addition, for personnel, we are promoting rehydration and salt supplementation with salt candies, installing spot coolers, and introducing air-conditioned clothing. With these measures in place, many of the workers at sites say that the work has become easier, which has also led to more efficient work.

In recent years, we have also started to prioritize automation and the use of IoT technology in our manufacturing processes. By partially automating manual tasks, we can both reduce workloads and the risk of injuries or accidents. The safety of our employees is our number one priority, and we are taking the necessary actions in each workplace in line with our commitment to creating clean, functional, and people-friendly working environments.

However, there are some sites where countermeasures are not yet sufficient, and further improvements are necessary. We will continue to consider the safety of our employees and implement measures geared to conditions at each worksite.

Initiatives to prevent occupational accidents

TOCALO is thoroughly committed to a safety-first policy and aims to achieve zero occupational accidents.

In fiscal 2024, the Company recorded 14 occupational accidents (0 fatalities, 6 lost-time accidents).

When a work-related accident occurs, we immediately disseminate the information to all worksites. The Group safety and health meetings investigate the causes and discuss countermeasures, which are then horizontally implemented at all worksites.

Our activities to prevent accidents before they occur includes sharing information at the Group safety and health meetings about injury accidents as well as about near-miss and other incidents that had potential to lead to serious accidents.

| Type of accident | Incident status | ||||||

|---|---|---|---|---|---|---|---|

| Fiscal 2019 | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | Fiscal 2023 | Fiscal 2024 | ||

| Occupational accidents | Employees who missed work because of injury or illness | ー | 5 | 1 | 3 | 5 | 6 |

| Number of days | ー | 48 | 1 | 43 | 245 | 79 | |

| Fatalities | ー | 0 | 0 | 0 | 0 | 0 | |

Occupational health and safety management system

All of our business sites have acquired and are operating under ISO 45001:2018 certification (the international standard for occupational health and safety management systems) and JIS Q 45001 certification, which has additional requirements for daily health and safety activities.

We are constructing a safe and healthy work environment by conducting risk assessments aimed at reducing and controlling safety and health risks and by supervising compliance with laws and regulations.

We are promoting the acquisition of ISO 45001 certification, and 28.6% of the consolidated Group have currently obtained certification.

Please see the ESG Data Sheet for Group company ISO 45001 status.

| Plants with certification | Registered date | Registration number |

|---|---|---|

| Kitakyushu Plant | March 2019 | ISO45001:JISHA-O-102 |

| March 2024 | JQA-OH0290 | |

| Nagoya Plant | December 2023 | ISO45001:JISHA-O-105 |

| December 2023 | JISQ45100:JISHA-105 | |

| Kobe Plant | December 2023 | ISO45001:JISHA-O-104 |

| December 2023 | JISQ45100:JISHA-104 | |

| Kurashiki Plant | January 2024 | ISO45001:JISHA-O-111 |

| January 2024 | JISQ45100:JISHA-111 | |

| Akashi Plant | September 2024 | ISO45001:JISHA-O-122 |

| September 2024 | JISQ45100:JISHA-122 | |

| Thermal Spraying Technology R&D Laboratories | November 2024 | ISO45001:JISHA-O-124 |

| November 2024 | JISQ45100:JISHA-124 | |

| Tokyo Plant Suzumi Workshop | January 2025 | ISO45001:JISHA-O-129 |

| January 2025 | JISQ45100:JISHA-129 | |

| Tokyo Plant Gyoda Workshop | January 2025 | ISO45001:JISHA-O-130 |

| January 2025 | JISQ45100:JISHA-130 |