SustainabilitySocietyQuality management and customer satisfaction

We are aiming to be a company trusted by customers and are striving to provide products and services that satisfy customer requirements.

We also want our business partners to grow

alongside us through activities based on our partnerships.

Enhancing customer satisfaction

Working daily to deliver inspiration to customers

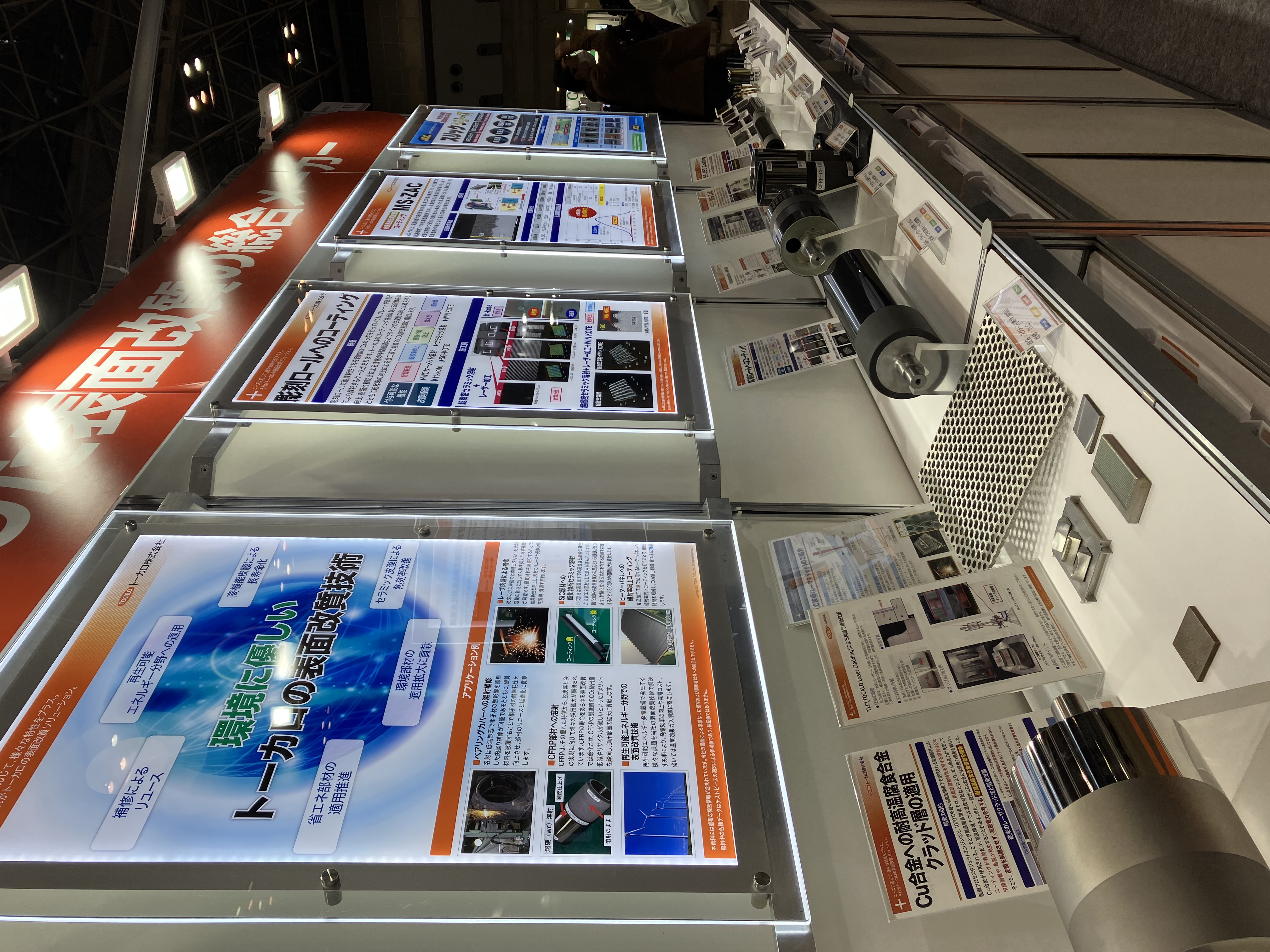

- April: Sea Japan 2024 (combined with Offshore & Port Tech 2024) (Tokyo Big Sight)

- April: 2024 International Welding Show (Intex Osaka)

- June: 36th Manufacturing World Tokyo (Tokyo Big Sight)

- September: 1st Kyushu Semiconductor Industry Exhibition (Marine Messe Fukuoka)

- October: 27th Manufacturing World Osaka (Intex Osaka)

- December: SEMICON Japan 2024 (Tokyo Big Sight)

- January: 39th NEPCON Japan (Tokyo Big Sight)

Etc.

EMPLOYEE VOICES

We are solving environmental issues while building trust with our customers.

Atsushi Nasu

Sales Division/Kanagawa Sales Office,

Tokyo Plant Suzumi Workshop

Energy conservation in power-hungry manufacturing plants has become a major priority for the semiconductor industry amid a growing focus on environmental issues. TOCALO’s thermal spray heater technology can deliver heat directly and efficiently to a designated area. By minimizing waste heat, this technology contributes significantly to our customers’ energy conservation efforts. The response to this innovation has been very positive, including the emergence of a growing number of new business opportunities.

By providing comprehensive solutions to environmental challenges, we are able to build trust with our customers. This leads to the discovery of new technical needs and business opportunities. While no single technology can address every energy-saving challenge, we are confident that by responding to expectations toward our comprehensive technological capabilities in the semiconductor field and beyond, we can contribute to an expanding range of fields. We will continue to work alongside our clients to build a sustainable society.

Quality Policy

TOCALO quickly formulates and submits product and service proposals using its surface modification technology to fulfill customer needs and continuously improve quality.

- Create products that fulfill customer quality requirement

- Clarify and strictly adhere to quality standards

- Set quality targets and evaluate degree of attainment

- Continuously improve the quality management system

Acquisition of ISO 9001 certification

All plants have acquired certification.

We continually improve our quality management system in order to improve customer satisfaction and earn social trust through quality assurance.

| ISO 14001-certified plant | Registered date | Registration number | Certified activities |

|---|---|---|---|

| Kitakyushu Plant | Jul. 1998 | JQA-2470 | Thermal spray processing for industrial machinery parts, equipment parts for the chemical industry, and parts for FPD and semiconductor manufacturing equipment |

| Tokyo Plant | May 1999 | JQA-QM 3344 | Surface treatment processing for industrial parts (thermal spray processing and other peripheral technologies) |

| Akashi Plant | Oct. 1999 | JQA-QM 3810 | Surface treatment processing for industrial parts (thermal spray processing and other peripheral technologies) |

| Kobe Plant | May 2003 | JQA-QMA 10001 | ZAC processing of parts for FPD and semiconductor manufacturing

equipment

TD processing of insert block molds for automobile forming mold |

| Kurashiki Plant | Dec. 2011 | JQA-QMA 14492 | Surface treatment processing for industrial parts (thermal spray processing and other peripheral technologies) |

| Nagoya Plant | Nov. 2017 | JQA-QMA15690 | Surface treatment of parts for general industrial and aerospace industries (thermal spraying) |

| Process | Implementation items | Certified activities |

|---|---|---|

| Considering orders |

|

|

| Process | Implementation items | Certified activities |

|---|---|---|

| Orders (processing instructions) |

Processing directives

|

|

| Process | Implementation items | Certified activities |

|---|---|---|

| Manufacturing |

|

|

| Process | Implementation items | Certified activities |

|---|---|---|

| Shipment |

|

|

| Process | Implementation items | Certified activities |

|---|---|---|

| After-sales service |

|

|

Acquired JIS Q 9100, Nadcap certification (for the aerospace industry)

The Nagoya Plant has acquired certification for the aerospace industry.

JIS Q 9100 was established to manage the quality of aerospace defense products, which

requires advanced quality control. To satisfy requirements specific to the aerospace

industry, the Nagoya Plant acquired certification in November 2008. The Akashi Plant was

also certified in 2014, but the aircraft-related work was consolidated at the Nagoya Plant,

and the certification was returned at the end of March 2020.

Nadcap is an international

certification system under which the Performance Review Institute (PRI), an NPO in the

United States, reviews special process operations in the aerospace and defense industry.

| ISO 14001-certified plant | Registered date | Registration number | Certified activities | |

|---|---|---|---|---|

| JIS Q 9100 | Nagoya Plant | Nov. 2008 | JQA-AS 0044 | Surface treatment of aerospace components (thermal spraying) |

| Nadcap | Mar. 2014 | 9676204446 | Surface treatment of aerospace components (thermal spraying) |