SustainabilityEnvironmentWaste reduction and environmental conservation

TOCALO is constantly monitoring the environmental impact of its business activities, products, services, and strive to prevent pollution.

Through the reduction of waste and the appropriate management of hazardous substances, TOCALO is committed to continuous improvement.

Appropriate management of chemical substances

In accordance with the PRTR Law, we report the amounts of chemical emissions and transfers.

In fiscal 2024, TOCALO reported the amount of designated chemicals released into the environment and transferred for seven substances in accordance with the PRTR Law (Pollutant Release and Transfer Register: Chemical Substance Release and Transfer Notification System). The emissions met all regulatory standards under the act.

| Released amount (kg) | Transferred amount (kg) | |||||

|---|---|---|---|---|---|---|

| Emission into the atmosphere |

Release into public waters |

Discarding into the soil at place of business |

Landfill disposal at place of business |

Transferring to sewerage |

Transferring off-site (industrial waste) |

|

| Chrome and trivalent chrome compounds |

5.6 | 0 | 0 | 0 | 0 | 4,360 |

| Cobalt and its compounds |

1.5 | 0 | 0 | 0 | 0 | 917 |

| Toluene |

|

0 | 0 | 0 | 0 | 73 |

| Nickel | 6 | 0 | 0 | 0 | 0 | 5,780 |

| Nickel compounds | 4.1 | 0 | 0 | 0 | 0 | 990 |

| Boron compounds | 0.0 | 0 | 0 | 0 | 2 | 10,500 |

| Silicon carbide | 49 | 0 | 0 | 0 | 0 | 10,700 |

- The amount of toluene released into the atmosphere is 1,200 kg. Toluene is contained in organic solvents, such as thinners. The amount of volatile organic compounds (VOCs) evaporated due to natural drying is estimated based on the quantities used.

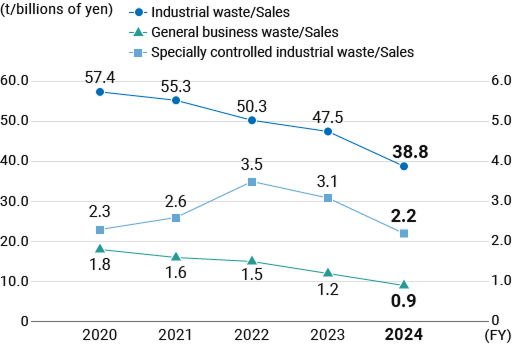

Waste Reduction

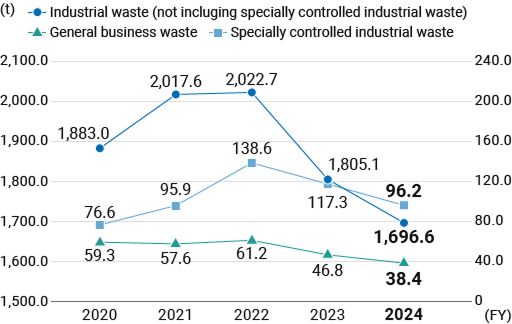

We are properly disposing of all types of waste, from general waste to specially controlled industrial waste.

- General waste

Paper constitutes the majority of business-related general waste, and we are committed to reusing and recycling paper. When confidentially is an issue, we work with the paper manufacturers to dissolve materials chemically. - Industrial waste

Waste oil accounted for 34% of our industrial waste, which was the largest component. Waste oil emits from cooling water that is added to grinding oil for use as a coolant with wet grinders (machines for roll grinding). More than 90% of the water is tap water. After disposal, it is used at cement factories and elsewhere to adjust combustion temperature.

Sludge made up 26% of our industrial waste, waste alkali 10%, mixed waste 9%, while slag, waste plastic, and glass and ceramic scraps accounted for 6% each.

The majority of the sludge and waste alkali is waste liquid after cleaning, and most of it is water. We plan to install a system to distill and filter this water for reuse.

Mixed waste is defined as a mixture of several types of waste that is difficult to sort.

Slag refers to residue thermal spray material, such as waste blasting material and collected fumes.

Waste plastics include material containers and secondary materials, as well as waste paper and wood scraps that contain oil.

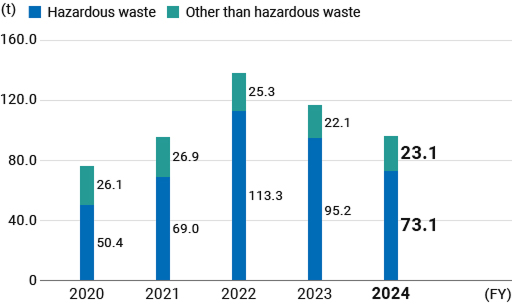

Glass and ceramic scraps, such as refractory bricks, contain ceramic-based grinding materials that cannot be recycled. - Specially controlled industrial waste

Most of this waste is dust generated by thermal spraying using chromium-containing materials (such as stainless steel) and collected by a dust collector. When the dust volume exceeds the regulatory limit in dissolution tests, it is disposed of as specially controlled industrial waste.

VOICE

Creating a virtuous cycle for the environment and our business through the reduction of waste oil

Toshiro Izumi

Machining Process Department 2, Production Division 2, Akashi Workshop.2,Akashi Plant

My work at the Akashiharima Plant primarily involves machining (processing work that involves the use of machine tools), and I am also responsible for equipment maintenance. My day-to-day tasks include management of the water-soluble grinding oil used in the grinding process for semiconductor manufacturing equipment components (thermal sprayed parts). Grinding oil deteriorates with continued use and must be regularly replaced. This results in the discharge of waste oil, which must be handled appropriately by a wastewater treatment company, using oil-water separation, filtration, and other processes.

In the past, we generated around 360 tons of waste oil each year. This resulted in a significant workload for maintenance staff, since we had to arrange for the disposal and transportation of the waste oil and handle associated administrative tasks.

In 2023 we installed a new treatment system with the aim of enhancing the efficiency of waste oil disposal. The new system slashed the amount of waste oil volume generated each year by 95%, from 360 tons to just 18 tons. In addition, we were able to cut waste oil treatment and transportation costs by around 50%, while also lowering CO2 emissions. Our operating efficiency was further improved through the reduction of administrative tasks relating to waste oil collection.

I take great care to ensure that the treated wastewater discharged from our waste oil treatment systems is within the wastewater standards set by the local government. I keep the system operating normally by regularly replacing and cleaning consumable parts, and I analyze treated wastewater at appropriate intervals to verify its safety.

We are now exploring ways to cut waste still further by preventing contamination of the grinding oil during use, in order to reduce both treatment loads and the frequency with which consumable parts are replaced. Going forward, we will look at the possibility of implementing these improvements at other business sites. We will also work with thermal spraying and grinding staff to reduce material and energy losses by optimizing the thickness of thermal spray coatings. We will continue our efforts to protect the environment and achieve company-wide waste reductions.

TOPICS

Introducing translucent clear paper files

Recycling of miscellaneous recyclable paper at Headquarters (Kobe City)

Kobe City has been implementing an initiative for the recycling of used paper (miscellaneous recyclable paper) that is emitted by business operators targeting the business operators of Port Island and Rokko Island, and the TOCALO Headquarters (within Kobe City Port Island) has been participating in this initiative since March 2020. A large amount of shredder dust is generated at the Headquarters, and this is recovered and transported to designated locations in Kobe City by contracted transport companies.

Air pollution prevention

Dust generated in the thermal spraying process is safely collected before it can be released into the atmosphere.

Soil and water pollution prevention

Soil and water pollution prevention is particularly critical because soil and water quality directly affect surrounding communities.

Noise countermeasures

Noise barriers have been installed and noise measurements are also carried out regularly.

Reduction of water usage

We are actively working to reduce water consumption by collecting and storing water in underground tanks for reuse.

Supporting environmental organizations

You can find out more about TOCALO’s contributions to society at the following links.

For further information, click here:

Green Donation Funds:https://www.green.or.jp/english/