SustainabilityEnvironmentEnvironmental management

We have established an environmental management system at all of our sites and are making continuous improvements based on proper operation.

Basic philosophy

Basic environmental philosophy

TOCALO recognizes that “continuously improving the global environment and preventing pollution” is one of the most important challenges of our time. Our basic environmental philosophy is to use surface modification technologies to save resources, save energy, and reduce our environmental impact to protect the global environment and contribute to society.

Environmental policy

TOCALO follows its basic environmental philosophy in all activities, products, and services related to the manufacture and sale of its surface modification technologies. Following is a summary of policies we follow in our efforts to continuously improve our environmental performance.

- Constantly recognize the environmental impact of our activities, products, and services, and establish, implement, and maintain an environmental management system.

- Commit to preventing environmental pollution, using sustainable resources, implementing climate change measures, and preserving water environments.

- Commit to continuously improving our environmental management system.

- Comply with environmental laws and regulations relating to our operations, products and services, as well as other requirements to which we agree.

- Based on our environmental policy and considering the potential environmental impact of

our activities, products, and services, set environmental targets and engage in

activities in the following areas to contribute to improving the environment:

- Energy and resource conservation in business activities

- Environmental contribution through promotion of business activities

- Climate change measures

- Water environment preservation

To successfully implement this policy, we will set environmental targets and contribute to environmental conservation by bringing together the strengths of all our divisions and all levels of our workforce.

April 1, 2025

Kazuya Kobayashi

President and CEO, Representative Director

TOCALO Co., Ltd.

Environmental management organization structure

Promotion of ISO14001

Certified at all sites

We are continually improving our environmental management system to contribute to society and

protect the

global environment by conserving resources and energy and reducing our environmental

impact.

Since

acquiring ISO 14001 certification at all our sites in 2012, we have maintained our 100%

certification rate

even when relocating or launching new sites.

We are promoting the acquisition of ISO 14001 certification, and 57% of consolidated Group companies have currently obtained certification.

Please see the ESG Data Sheet for the ISO 14001 status of consolidated Group companies.

Status of ISO 14001 certification (certification number JQA-EM2253) (In order of registration date)

| Acquisition of certification Plants and research laboratories |

Expansion of certified sites |

|---|---|

| Headquarters | March 2002 |

| Thermal Spraying Technology R&D Laboratories | March 2002 |

| Kitakyushu Plant | September 2005 |

| Nagoya Plant | September 2006 |

| Kobe Plant | September 2006 |

| Tokyo Plant Gyoda Workshop | September 2007 |

| Kurashiki Plant *Name changed to Kurashiki Plant in 2022 upon relocation of the former Mizushima Factory. | September 2007 |

| Akashi Plant | September 2009 |

| Miyagi Technical Service Center | August 2012 |

| Tokyo Plant Suzumi Workshop | August 2018 |

History of ISO14001 certification

| March 2002 | Headquarters and Thermal Spraying Technology R&D Laboratories were the first sites in TOCALO to acquire ISO14001 certification. |

|---|---|

| October 2004 | Thermal Spraying Technology R&D Laboratories relocated from Higashinada-ku, Kobe City to the Minami-Futami Industrial Park, Akashi City. |

| September 2005 | The registered address of Thermal Spraying Technology R&D Laboratories changed to the new address. |

| Kitakyushu Plant was the first plant to acquire certification. | |

| September 2006 | Nagoya Plant, Kobe Plant, and Akashi No.3 Plant acquired certification. |

| September 2007 | Tokyo Plant (Gyoda Workshop) and Mizushima Plant acquired certification. |

| September 2009 | Akashi Plant acquired certification. All major TOCALO sites were certified. |

| October 2010 | Akashi Plant No.3 relocated and integrated with Akashi Plant. |

| July 2011 | Miyagi Technical Service Center was established in Miyagi Prefecture. |

| September 2011 | Each sales office acquired certification. |

| Certification of Akashi Plant No.3 was cancelled. | |

| August 2012 | Miyagi Technical Service Center acquired certification. All TOCALO sites were certified. |

| August 2014 | Kobe Plant relocated from Higashinada-ku, Kobe City to Nishi-ku, Kobe City. The former plant, where some production processes remained, became the Fukae branch office of Kobe Plant. |

| December 2014 | Akashi-Harima Plant acquired and placed under the control of Akashi Plant. |

| September 2015 | The registered address of Kobe Plant changed to the new address. |

| February 2016 | Nagoya Plant relocated from Midori Ward, Nagoya City to Tokai City, Aichi Prefecture. |

| September 2016 | Akashi-Harima Plant acquired certification following the start of full-scale operations. |

| The registered address of Nagoya Plant changed to the new address. | |

| August 2017 | Headquarters relocated from Fukae, Higashinada-ku, Kobe City to Minatojima (Port Island), Chuo-ku, Kobe City. |

| September 2017 | The registered address of Headquarters changed to the new address. |

| August 2018 | Tokyo Plant No.2 (Suzumi Workshop) was newly certified following partial relocation (Gyoda Workshop) |

| July 2020 | The Kita-Kanto Sales Office relocated. |

| August 2020 | The registered address of Kita-Kanto Sales Office changed to the new address. |

| April 2022 | The registered name of Mizushima Plant changed to Kurashiki Plant and the registered address changed from Matsue, Kurashiki City to Unozu, Kojima, Kurashiki City. The former Mizushima Plant remained as a sub-plant of Kurashiki Plant. |

| September 2022 | The registered name of Tokyo Plant (Gyoda Office) changed to Tokyo Plant Gyoda Workshop. |

| The registered name of Tokyo Plant No.2 (Suzumi Workshop) changed to Tokyo Plant Suzumi Workshop. | |

| The registered name of Mizushima Plant changed to Kurashiki Plant and the registered address changed to the new address. | |

| July 2024 | Yamanashi Sales Office relocated. |

| September 2025 | The registered address of Yamanashi Sales Office changed to the new address. |

| Tokyo Plant Gyoda Workshop changed the scope of activities. | |

| Certification of Mizushima Plant was cancelled. |

VOICE

We are using innovative communication methods to reduce waste in ways that allow the entire plant organization to share a sense of achievement.

Yuki Nakakuki (Quality Control Department 1, Suzumi Workshop, Tokyo Plant)

Akihiro Sato (Machining Process Department, Production Division 1, Suzumi Workshop, Tokyo Plant)

Yusuke Kurosaki (Spraying Department 1, Production Division 1, Suzumi Workshop, Tokyo Plant)

In addition to our main duties, we also serve as members of the Environmental Control Committee. We are jointly responsible for various environmental measures, including efforts to reduce waste and electricity consumption, and we work together to achieve our targets in these areas. As parents, we share a common commitment to contributing to the protection of the future.

In fiscal 2024, we prioritized general waste reduction. We introduced dedicated carts in each workplace to ensure thorough separation of different waste types, such as paper bags for blasting materials and tape cores. These efforts resulted in a year-on-year decrease of over 200 kg in waste, far exceeding our original target of 100 kg.

One of the most challenging aspects of environmental initiatives is communication. To gain the understanding and cooperation of the staff at the Suzumi Workshop, we used plant-wide morning meetings and hazard prediction sessions as opportunities to inform people about initiatives toward our environmental targets and the areas in which we needed their support, using clear and simple materials. We were surprised to find that all employees were more cooperative than we initially expected. The number of inquiries about waste sorting and disposal has risen recently. We see that as a sign of growing interest in environmental issues.

Going forward, we will continue to prioritize communication and understanding while working to visualize both our processes and results. We will also continue to target further mitigation of environmental impacts through initiatives that foster a shared sense of achievement throughout the plant organization.

Scope of application

The scope of application of the environmental management system applies to the business activities of TOCALO Co., Ltd.

(1) Target organization

TOCALO Co., Ltd.

Headquarters / Miyagi Technical Services Center / Tokyo Plant Gyoda

Workshop / Tokyo

Plant Suzumi Workshop / Nagoya Plant / Kobe Plant / Akashi Plant / Thermal Spraying

Technology R&D

Laboratories / Kurashiki Plant / Kitakyushu Plant

(2) Certified activities

R&D, manufacturing, sales, and after-sales service of surface modification products using thermal spray and peripheral technologies

(3) Location (physical scope) and scope of activities

The contents are in accordance with matters registered with JQA.

| Organization name | Address | Scope of activities |

|---|---|---|

| ①Headquarters, TOCALO Co., Ltd. | 6-4-4 Minatojima Minamimachi, Chuo-ku, Kobe, Hyogo | Corporate management and support operations at the Headquarters |

| ②Miyagi Technical Service Center (Miyagi TSC), TOCALO Co., Ltd. | 21-11 Kitanaka Bessho, Kawauchi, Osato-Cho, Kurokawa-Gun, Miyagi | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

| Yamanashi Sales Office, TOCALO Co., Ltd. | 5F, Sumitomo Life Kofu Marunouchi Building, 3-32-11 Marunouchi, Kofu, Yamanashi | Sales and after-sales service of surface modification products using thermal spray and peripheral technologies |

| ③Tokyo Plant (Gyoda Workshop), TOCALO Co., Ltd. | 1-1-1 Gyoda, Funabashi, Chiba | Manufacture and after-sales service of surface modification products using thermal spray technologies |

| ④Tokyo Plant No.2 (Suzumi Workshop), TOCALO Co., Ltd. | 606-5 Suzumi-cho, Funabashi, Chiba | Manufacture, sale, and after-sales service of surface modification products using thermal spray and peripheral technologies |

| Kanagawa Sales Office, TOCALO Co., Ltd. | 1-14-20 Shinyokohama, Kohoku-ku, Yokohama, Kanagawa | Sales and after-sales service of surface modification products using thermal spray and peripheral technologies |

| Kita-Kanto Sales Office, TOCALO Co., Ltd. | 2F, 1086-45 Shimohamada-cho, Ota, Gunma | Sales and after-sales service of surface modification products using thermal spray and peripheral technologies |

| ⑤Nagoya Plant, TOCALO Co., Ltd. | 33-3 Nibanwarishimo, Nawamachi, Tokai, Aichi | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

| Shizuoka Sales Office, TOCALO Co., Ltd. | Fujioji Bldg.102, 411-1, Motoichiba, Fuji | Sales and after-sales service of surface modification products using thermal spray and peripheral technologies |

| ⑥Kobe Plant, TOCALO Co., Ltd. | 1-5 Mitsugaoka, Nishi-ku, Kobe, Hyogo | Manufacture and after-sales service of surface-modified products using thermal spray and peripheral technologies |

| ⑦Akashi Plant, TOCALO Co., Ltd. | 14-1, Minamifutami, Futami-cho, Akashi, Hyogo | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

| Akashi Plant (Akashi-Harima Plant), TOCALO Co., Ltd. | 15-1 Higashi-Shinjima, Harima-cho, Kako-gun, Hyogo | Manufacture and after-sales service of surface modification products using thermal spray technologies |

| ⑧Thermal Spraying Technology R&D Laboratories, TOCALO Co., Ltd. | 14-3 Minamifutami, Futami-Cho, Akashi, Hyogo | Research and development of surface modification products using thermal spray and peripheral technologies |

| ⑨Kurashiki Plant, TOCALO Co., Ltd. | 2030-28, Kojimaunotsu, Kurashiki, Okayama | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

| Mizushima Plant, TOCALO Co., Ltd. | 2-38, 2-chome, Matsue, Kurashiki City, Okayama | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

| ⑩Kitakyushu Plant, TOCALO Co., Ltd. | 1-48 Torigoe-cho, Kanda-cho, Kyoto-gun, Fukuoka Prefecture | Manufacture, sale, and after-sales service of surface modification products using thermal spray technologies |

(4)Scope of impact

Within the site

- Design and development

- Improvement of production processes

Environmental aspects of the interface are as follows.

- Energy management

- Purchasing management

- Outsourcing Management

- In-house subcontracting management of other plants

- Waste management

- Distribution, use, and disposal of products after use

- Service management

Compliance with environment-related laws and regulations

Identifying laws and regulations to be observed and confirming the status of compliance

TOCALO compiles a list of environmental laws and regulations to be observed and regularly

checks the

status of compliance. Details of compliance include notifications to the government,

appointments, and

regulatory values.

To date, we have not been subjected to fines or punishment in

relation to

environmental laws.

Major environmental laws and regulations related to TOCALO's business

| Waste Management and Public Cleaning Law | Air Pollution Control Law |

| Water Pollution Control Law | Sewerage Law |

| Soil Contamination Countermeasures Act | Septic Tank Law |

| Noise Regulation Law | Vibration Regulation Law |

| Offensive Odor Control Law | Factory Location Law |

| Act on Rational Use and Proper Management of Fluorocarbons | Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof ("PRTR Law") |

| Poisonous and Deleterious Substances Control Law | Fire Service Act |

| Industrial Safety and Health Act | High Pressure Gas Safety Act |

| Law Concerning the Promotion of the Measures to Cope with Global Warming | Act on Rationalizing Energy use and Shifting to Non-fossil Energy |

| Act on Promotion of Resource Circulation for Plastics |

Environmental accounting

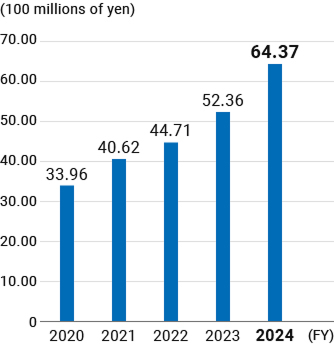

We focused on investing in environmental facilities, such as wastewater and waste gas treatment systems, and noise-prevention measures at new plants.

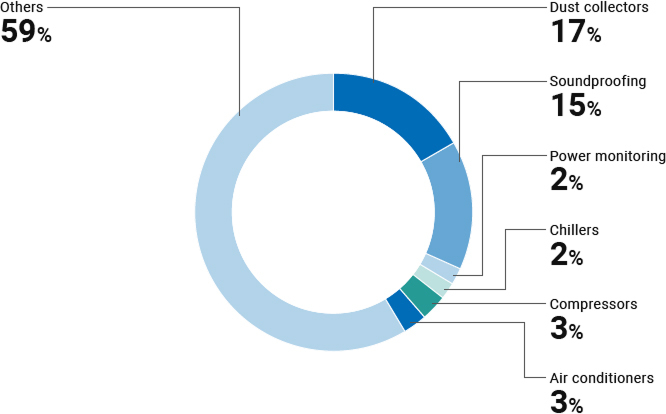

The graph below shows the cumulative amount of environment-related capital expenditures. Our main environmental facilities include dust collectors to prevent dust emissions, soundproofing equipment to block noise from the dust collectors, and energy-saving equipment.

Investment was higher than usual in fiscal 2024 due to the installation of new equipment at the newly constructed Kobe Plant No. 2, as well as a new administration building at the Kitakyushu Plant. As in the previous fiscal year, we also continued to install soundproofing equipment and upgrade our dust collectors.

Environmental education and training

We provide general education for all employees.