Climate change, resource depletion, and other environmental conditions caused by global warming are intensifying to the point that they are becoming serious threats to the survival and prosperity of humankind and global society. Our highly refined surface modification technologies offer functions, such as heat, corrosion, and wear resistance, that reduce greenhouse gas emissions by lowering energy consumption, and reduce the consumption of resources by extending the useful life of parts and products.

Preventing global warming ❶Reduce manufacturing equipment energy consumption

Eliminating unnecessary heat

The key to reducing greenhouse gas emissions that contribute to climate change is to lower the amount of energy consumed, which is the fundamental source of the emissions. TOCALO contributes to reducing the energy needed to operate industrial equipment by applying coatings with properties improve heat radiation from heating mechanisms.

For example, for a device that heats in a reduced-pressure environment with less heat medium (atmosphere), in certain conditions our coatings can shorten the heating period by 40% or lower the heating mechanism temperature by about 10%, both of which reduce the amount of energy consumed.

In addition, our coatings enable more consistent heating within the chamber, enabling more uniform results, such as when air-roasting nuts. This improves product quality and yield while also reducing the amount of energy required for heating.

One-step coating for large parts

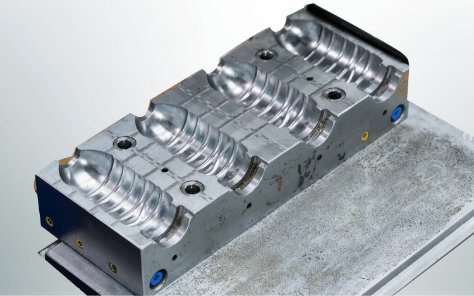

In most cases, molding or casting one large part made of resin or metal consumes less energy, in the form of electricity or gas, than molding and assembling many parts. The processes for both molding and casting entail pouring a heat-melted material into a die and cooling the resin or metal material by allowing heat to dissipate through the die. Large dies are prone to producing flawed products because the heated material has the potential to cool and harden before completely filling the die.

A ceramic coating on the mold surface can solve these problems. The ceramic holds the heat longer than the mold, giving the heated material a little more time to spread and fill even a large die before it cools and hardens. The coating also reduces the number of dies needed and reduces the workload at the factory by decreasing the amount of storage and maintenance work.

Maintaining ideal conditions for rotating objects

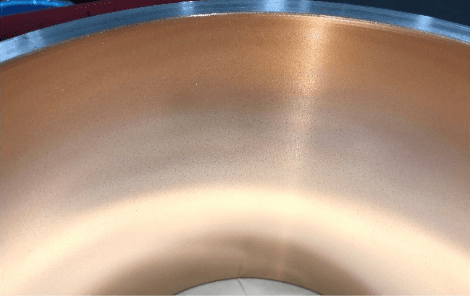

The key components of generators and air compressors are the parts that rotate in air flow. However, the air that comes in contact with the parts can cause erosion or deposit particles that destabilize the rotation balance which, over time, can lead to significant energy loss.

Applying the optimum coating to surface areas that come in contact with the air flow can dramatically slow the wear and accumulation of particles on a part and preserve the part’s initial ideal condition for an extended period of time.

Reducing the weight of rotating parts

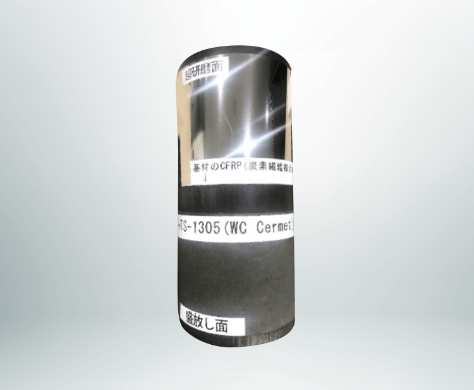

Machine parts made of carbon fiber-reinforced polymer (CFRP) have been gaining widespread usage in recent years. CFRP contributes to preventing global warming because it is lighter than metal and requires less energy to move and rotate. However, CFRP cannot replace some metal rotating parts because they must be highly wear-resistant.

TOCALO has the technology to spray CFRP parts with a hard cermet alloy coat and mirror-finish, creating CFRP rotating parts that are high-durability, lightweight, and energy efficient.

Preventing global warming ❷Promoting the use of renewable energy

Improving wind turbine durability

Wind power is a renewable energy generated from nature. Already widely use in the power infrastructure of Europe and the United States, the sight of large propellers of wind turbines is becoming increasingly common in Japan as well.

The bearings used in the power generations can be damaged by sparks emitted by the internal electric current. Our insulated bearings have a ceramic coating that protects the bearings and supports long-term, stable operation.

Protecting hydroelectric power equipment from dirt and sand

The river water used for hydroelectric power generation contains a mixture of large and small particles of dirt and sand. Without special care, this sediment can quickly wear the blades of the water turbines used to generate power, deteriorating their efficiency.

Tests of the sediment-resistant coating we developed showed it provides up to 19 times more durability than the commonly used pump parts made of high-chromium iron. Our coating also exhibits high toughness, making it impact resistant even against large rocks.

Longer life for biomass power equipment

Biomass is generally defined as renewable, biologically-derived organic resources other than fossil resources, with some familiar examples including food waste and livestock manure. Biomass power generation produces electricity from these resources by directly burning them or by converting them to gas.

TOCALO technology extends the life of boilers by providing a high temperature and corrosion resistant coating to boiler heat transfer tubes that are exposed to high temperature combustion gas and a wear-resistant coating to on the equipment parts that removes air polluting sulfur oxides from the smoke exhaust.

Preventing global warming ❸Improving automobile fuel efficiency

Enabling lightweight, high-tensile strength steel sheet

The automobile industry is making every effort to improve automobile fuel efficiency to reduce CO2 emissions. One step they are taking is to lighten the weight of vehicles by using steel sheet that is thin but still high strength.

TOCALO surface modification technology is being used to ensure stable production of high-tensile strength, high quality steel sheet. The conveyer rollers used in steel sheet production lines are prone accumulating foreign matter that causes scratches on the steel sheet. Our thermal spraying technology coats the rollers to prevent foreign matter from attaching to the rollers.

Conserving resourcesReducing materials used to restore machine part functionality

Restoring functionality with a fresh coating

TOCALO’s surface modification technology conserves resources and reduces waste by adding various functions and extending the life of machine parts. In addition, bushings, bearings, and other machine parts with coatings that have become worn and have reduced functionality due to extensive use can often be restored to full functionality by applying a fresh coating. Applying a new coat to machine parts eliminates the need to replace the parts and reduces the consumption of resources. TOCALO has also successfully developed a thermal spray ultra-low friction coating with exceptional friction and wear performance even without lubrication. The coating greatly reduces the amount of lubrication needed for bushings and bearings.